Background

Consistent behavior of high-performance optical structures requires maintenance of structural stability over the range of potential operating conditions. In practice, thermally induced aberrations are ubiquitous in optical systems and can limit the performance of optical devices such as gravitational wave detectors, deformable mirrors, lithographic systems, high power lasers, space optical instruments and telescopes, optical systems with femtosecond lasers, and ground-based telescopes.

Local transient or steady state thermal events can arise from many sources: routine system operation that produces internal thermal gradients, absorption of high-power beams by lenses and mirrors or exposure to asymmetric thermal heat sources. As a consequence, the temperature of optical elements increases, and for materials having a non-zero Coefficient of Thermal Expansion (CTE), the change of a temperature field induces deformations of optical elements and other system components that affect the optical response. In addition, the temperature changes can also alter the refractive index of a lens. These mechanical deformations and changes in the refractive index induce shifts in the focal response, as well as induce chromatic and spherical aberrations that can severely limit the performance of optical systems.

To develop optical system designs and operating conditions with reduced thermally induced aberrations, it is important that the effects of thermally induced fluctuations are understood and can be accurately simulated. Integrated Structural, Thermal and Optical Performance (STOP) analysis can help to understand the response of optical systems to thermally induced aberrations and be used to optimize system designs. STOP analyses are inherently multi-dimensional and multi-scale, and often couple structural mechanics, heat transfer and optical ray tracing. Thus, we need to know a large number of parameters that influence the system behavior and, in many cases, these parameters may be spatially heterogeneous or vary with time and temperature. For example, to accurately model an optical system with thermally induced deformations, we need to know CTEs, thermal contact resistances, refractive index, thermal conductivity, surface emissivity, etc., all of which may be temperature dependent. Furthermore, we also need to know the structural and thermal boundary conditions and equations governing the system dynamics.

Classical STOP analysis has one main limitation: the accuracy of the results is highly dependent on a prior knowledge of system parameters and equations governing the system dynamics. In this article, a framework for performing a fully integrated, single platform, multiphysics STOP analysis of an optical system is discussed and results of the simulation of thermal exposure on critical optical parameters performed using COMSOL Multiphysics® demonstrated. This approach can enable data driven simulations to optimize the performance of optical systems when subject to transient or steady state thermal exposure.

STOP Analyses

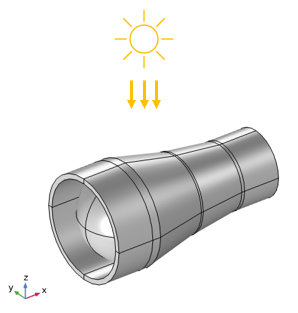

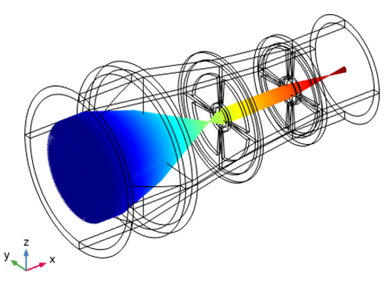

Thermal transients of optical systems may arise from the environment in which the device operates: heat sources in any associated control circuitry or highly localized absorption of energy passing through the optical components. As demonstration of an integrated multiphysics STOP analysis, let’s consider the response of an optical telescope exposed to solar radiation, Figure 1.

Figure 1. Solar exposure of optical telescope.

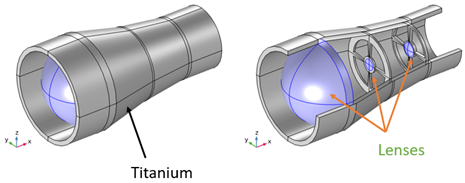

Inherently, a telescope is constructed of multiple materials: glass lenses that may or may not be coated, the telescope body that is ideally made from a single material that may have anisotropic properties and internal structural supports that may or may not match the telescope body. The design will most likely have variable thicknesses and contain asymmetric details as in Figure 2.

Figure 2. Example of possible construction details showing use of multiple materials.

Ultimately, the performance of the system is defined by the degree to which any thermal events cause structural changes that affect the optical performance. For effective product and technology development, these effects need to be known as early as possible in the design process. To simulate the optical performance accurately, we need to consider the following physics:

- Heat transfer

- Conduction

- Convection

- Radiation

- Structural mechanics

- Structural behavior: Isotropic or Anisotropic

- Joints, connections

- Physical restraints

- Optical reponse

- Geometrical optics

- Wavelength dependent refractive index

- Optical coating properties

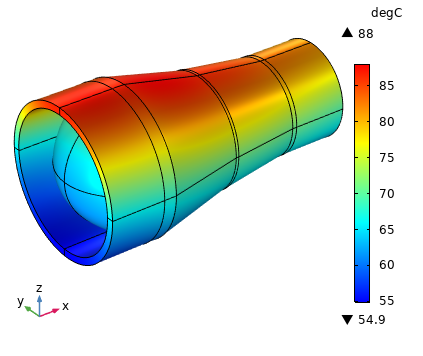

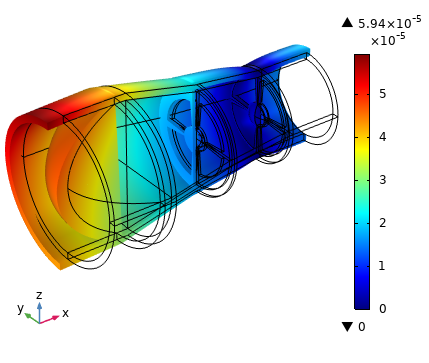

Depending on the nature of the thermal event, any simulation may be either transient or steady state which may give rise to additional loading events that could affect long-term structural lifespan. For a given steady state solar exposure, the simulated temperature distribution through the telescope structure is given in Figure 3 and the associated structural deformation in Figure 4.

Figure 3. Temperature distribution for steady state solar exposure.

Figure 4. Structural displacement due to solar exposure.

Structural deformation of the telescope changes the optical performance, the effect of which can be quantified using geometrical optics analyses, Figure 5.

Figure 5. Optical analysis using simulation of ray tracing.

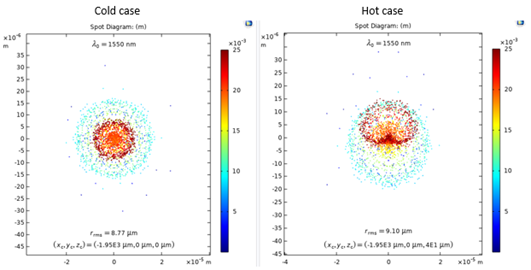

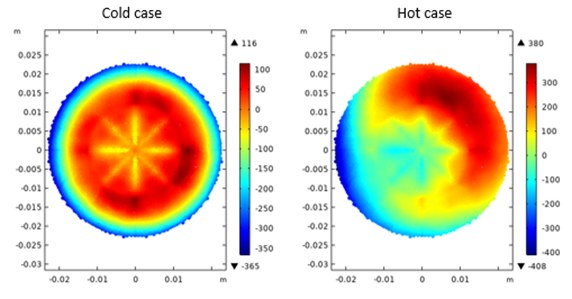

To calculate critical parameters characterizing wave front aberrations of interest to optical engineers, additional simulations can be integrated to provide parameters such as: the size of the focal spot, shift in focal point, optical path difference, and power distribution, Figures 6 and 7.

Figure 6. Distribution of rays at focal point after passing through the telescope optical components.

Figure 7. Optical path difference across lens for hot and cold thermal exposure.

Summary

This blog demonstrates the use of COMSOL Multiphysics® to provide an integrated multiphysics Structural-Thermal-Optical-Performance analysis to simulate thermally induced wave-front aberrations in optical systems. The results of these simulations can provide critical parameters to characterize thermally induced wave-front aberrations of interest to optical engineers. This information can be used to optimize the performance of optical systems prior to expensive and time-consuming prototype development and testing.