Getting to Market: Product Design and Development

After providing proof of concept for a new medical technology, device or development of second-generation devices, the next step is finalizing the product design. This is one of the most important stages in the development of a successful medical device since a flawed design may lead to it being ineffective or unsafe. Simulation can play an important role in the efficient development of safe and effective product designs.

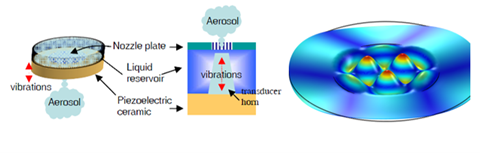

As an example, let’s consider the case of a device to provide controlled drug delivery to the lungs. To efficiently pass through the respiratory tract and reach the lungs, aerosol droplets must contain a specific size distribution and provide a sufficient dose to be clinically effective. To efficiently enter the respiratory tract, the aerosol must be integrated with an inhaler mask that can ensure controlled entry over a range of breathing regimes, Figure 3.1.

Figure 3.1: Droplet production through vibrating mesh.

In this particular product, a piezoelectric plate is excited in a controlled manner. The piezoelectric plate causes vibration of a mesh that interacts with a liquid reservoir to produce aerosol droplets having a characteristic distribution of droplet size that can be controlled by the displacement of the mesh during excitation.

Simulations of the PZT ceramic predicted the vibration behavior of the mesh and, when coupled with analyses of two-phase fluid flow, predicted the resulting aerosol volume and droplet size distribution. While the simulations enable identification of the operating conditions to produce the appropriate aerosol properties, successful development of the product requires that the aerosol droplets be integrated with the flow conditions associated with an inhaler mask to facilitate transport of the active species to the lungs. Design of the inhaler mask has to work for a range of breathing conditions and physical positions, while simultaneously ensuring passage of maximum doses of critical species into the lungs, Figure 3.2.

Figure 3.2: Breathing pattern and associated flow distribution.

Simulations of the multiphase fluid flow behavior of the combination of droplets and gas provide an understanding of the multiphase flow within the mask to ensure delivery of the vapor to the respiratory tract. The simulations investigated the flow behavior for a range of breathing modes, i.e. combinations of mouth and nose, and physical positions of the head and respiratory tract. The simulations can be extended to investigate the influence of alternative mask designs and operating conditions to provide optimization of the flow characteristics with effective droplet transport to the lungs. Integration of the flow behavior with geometric models of infant respiratory tracts predict passage of the droplets and delivery of critical drug species to the lungs. In this way, the most effective design and operating conditions can be identified without the need to build and test a range of physical prototypes.