Ceramic Matrix Composites – Solidifying it all

In the preceding Blogs on Ceramic Matrix Composites we have provided an outline of an intimately coupled multiphysics problem and how the controlling factors can be formulated to develop a predictive physics-based computational model. But what we really need to do if we are to help this technology develop and mature into real world applications is to take it out of the hands of the computational engineers and make it available for use by the manufacturing engineers responsible for developing the production technology that will give rise to real world components. To do this we need to remember that their skills lie in the production technology and not understanding nuances of complex multiphysics modeling.

In an attempt to provide analysis tools that the manufacturing world can use we have further developed the computational analysis discussed in the previous Blogs to allow domain specific users who are not experts in computational analysis to reliably use the computational analysis procedures through a user specific GUI to predict the CMC Manufacturing Process.

The computational tool operates in conjunction with COMSOL Multiphysics which provides the underlying finite element solver, geometry import and post processing capability. Two options of the software have been created:

- Option 1: Includes fluid flow, temperature, reaction kinetics, phase distribution.

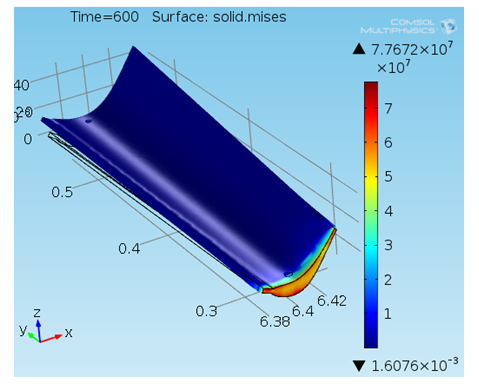

- Option 2: In addition to the phenomena above the residual stress and component distortion are predicted.

A user specific GUI provides input windows with restricted input screens for specific parameters, in addition predefined inputs that are of interest to users are available as default selections. This provides the user with great flexibility and also allows them to input proprietary data relevant for their specific manufacturing technology and materials.

The input data appear in two forms:

- Application specific: These data represent critical information that may be specific to the user’s CMC materials and processing; these data generally require some level of knowledge.

- User specific: These data sets are for proprietary information that individuals may have for their CMC system but is difficult to measure directly and for which limited information is available in the open literature.

The components of interest to the end user are of sufficient complexity that continued rebuilding for individual analysis is prohibitive. In addition to providing the capability for the user to define simple shapes that are variants on 3D rectangles, functionality has been included to import typical parts of interest from existing CAD files. The user is automatically provided with standardized data output for the following parameters:

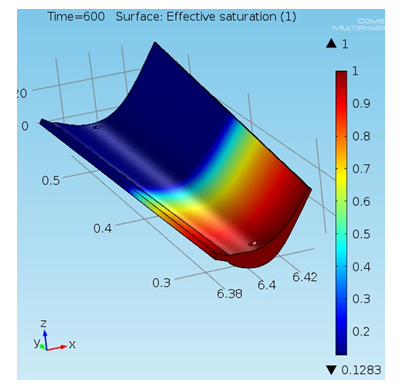

- Effective saturation

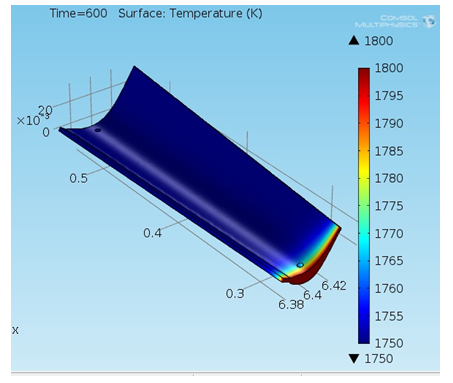

- Surface temperature

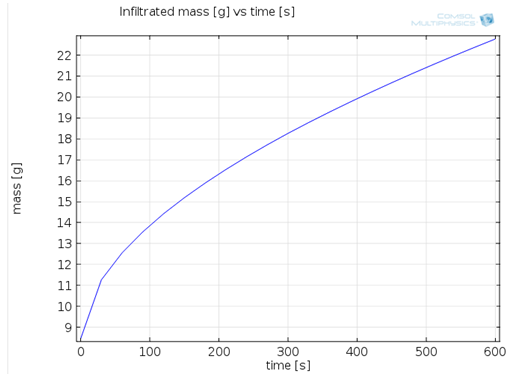

- Infiltrated mass as a function of time

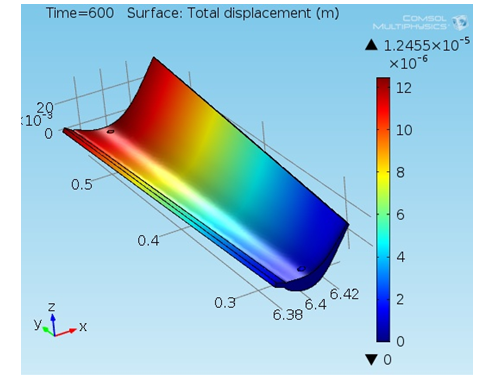

- Component displacement

- Residual stress distribution

Examples of typical output data are provided in Figures 8-12. Additional output of interest to the user can also be obtained through post-processing of the analysis file.

The functionality demonstrated here has been implemented using the existing Physics Interface Builder tool in COMSOL Multiphysics. Further development of the analysis tool will integrate this functionality with COMSOL’s Application Builder to further improve ease of use and extend application. Further information on these developments will follow in future blogs when available. Stay Tuned!