At AltaSim, we realize that customer needs related to electronic devices vary depending on time in the product design cycle, availability of validated thermal models, and selection of technology to meet cost, manufacturability, and thermal design targets. Integration of strategically designed computational simulations allows us to quantify the effects of specific design changes and the interrelationship between multiple variables thus providing a broad, yet metered view of the product design.

Demand for electronic devices with smaller sizes and improved processor and graphics functionality has resulted in higher power densities and thus significant increases in the heat generated at the component, board and system level. The higher operating temperatures can cause a significant reduction in the operating lifetime of electronic devices and thus managing the evolution, distribution and dissipation of thermal energy in electronic components and circuits is important for long term reliability.

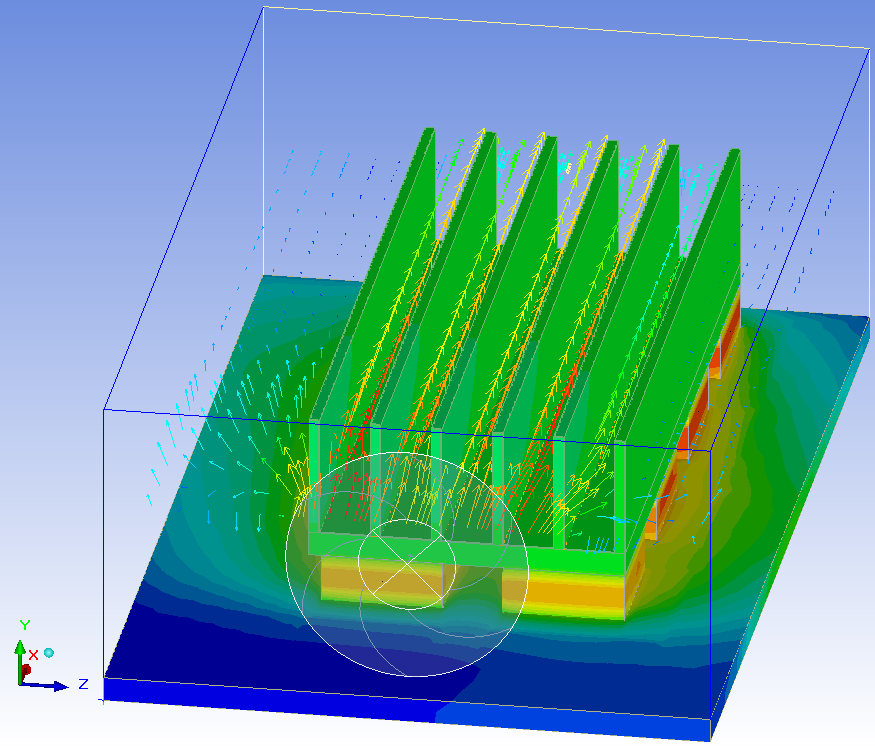

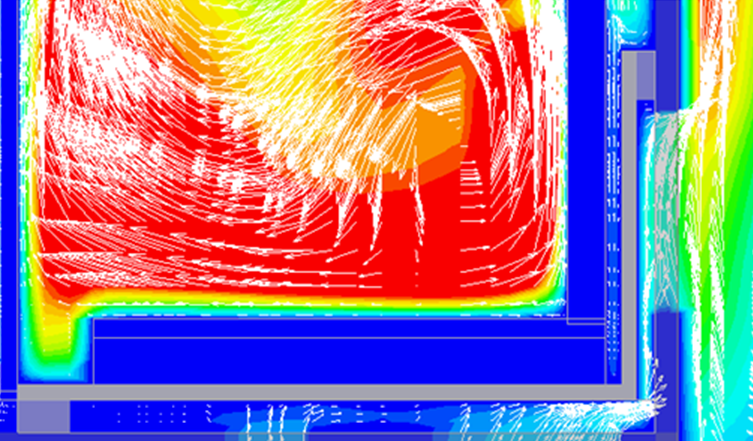

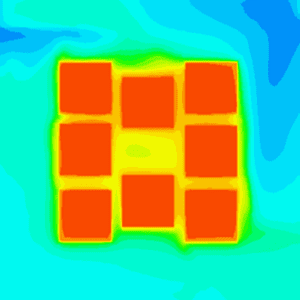

To help design individual components, board layouts, and integrated systems that can effectively dissipate thermal energy, AltaSim combines its expertise in thermal analysis and computational fluid dynamics with practical experience in applying ANSYS IcePak software.

Struggling with IcePak? Contact us about our IcePak consulting services.

Our knowledge of the most effective approach for developing the required level of detail for the application allows us to predict the effects of fluid flow and heat transfer at the component, board or system level, consequently AltaSim can provide:

- Improved design

- Optimized performance

- Reduced need for physical prototypes and testing

- Shortened time-to-market

Our expertise in this area has supported applications for products in manufacturing and processing industries, aerospace navigation and control systems, and consumer electronics products. Among the examples of applications that have been investigated are:

- Heat sink optimization for passive cooling of power electronic circuits

- Heat pipe design using fan assisted cooling

- Component layout and PCB thermal via connectivity

- Board assembly and lay up

- Rack mounted system design

Whether your present focus is local heat removal from a high-powered component, determining the ideal placement of IC packages in a system, identifying the flow rates needed for cooling, optimizing heat sink design, or managing dynamic power dissipation using a combination of multi-core processing, feedback controls, phase change materials, etc., AltaSim can support your team in the development of robust solutions for thermal management of electronic components and systems.

Contact us today, if you are interested in speaking with us about developing solutions for electronics cooling challenges.