Electric Vehicle Simulation

Using simulation and modeling techniques will reduce the costs associated with prototyping electric vehicles. This allows you to go to market faster by solving design issues yet to be defined, and increase quality and safety.

Why Work With Us?

Direct EV experience with large and small OEMs

Serving the automotive, commercial vehicle and motorsports industries for over 20 years

Over 100 million modeling and simulation hours

We work on every aspect of a vehicle – from the external aerodynamics to internal systems

We understand vehicle design and will recommend opportunities for improvement

Best-in-class simulation tools for structural, thermal, aerodynamic and multiphysics solutions

Our team of experts has the experience and knowledge to address every aspect of a vehicle.

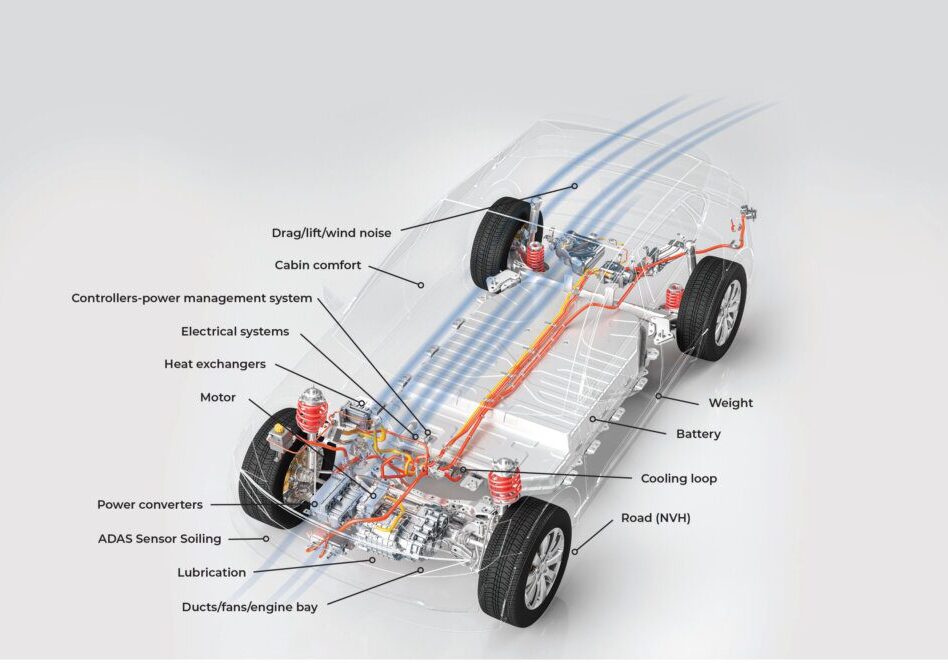

Problems We Solve

- Enhance total energy management

- Improve reliability

- Weight reduction

- Reduce running resistance

- Thermal management

- Extend range

- Thermal fatigue

- Extend battery life

- Fuel cell design

- Water and soiling management

- Occupant comfort

- ADAS Sensors – placement, soiling and interference

- Electromagnetic interference

Finding the Right EV Simulation & Modeling Partner Just Became A Lot Easier.

Altasim Technologies has formed a strategic partnership with TotalSim US to meet the unique design and production needs for EVs. Our combined teams are your single source engineering solution for modeling, simulation and thoroughly testing every aspect of your vehicle – inside and out.

Success Stories

Total Vehicle Review

Managing the balance between styling and performance is a challenge we often face and this was no different for a recent limited production, hybrid supercar development. We improved the cooling while preserving the radical styling, reduced drag and improved handling, and solved hot exhaust impingement issue.

Motor design

We completed a parametric study of a new starter design for an electric drive motor as well as identified methods of reducing weight and volume in motor design while increasing torque density. Our team also assessed effect of part thickness and materials of construction on the performance of the motor.

ADAS Sensors

We developed simulations of design concepts for advanced driver assistance systems. In one project, we assessed the effect of solar heating on the optical performance of sensors used for three-dimensional awareness of vehicle’s surroundings. In a second project, we assessed approaches for enclosing piezoelectric ultrasonic sensors behind the vehicle body.

Battery Cooling

Our team assessed the role of phase change materials in the thermal management of electric vehicle batteries. We also assessed the performance of an indirect liquid cooling system that circulates liquid coolant through pipes embedded in the battery. Finally, we reviewed design layouts to determine a design that provided the most uniform temperature within the batteries.

Drag Improvement

It is beneficial to incorporate simulation and modeling early in a design process; however, for various reasons that doesn’t always happen. With deadlines looming, we rapidly turned around over 25 cases in the first five days of working with an EV motorcycle manufacturer resulting in a substantial drag improvement while preserving the design styling.

Heat and Cooling System

Baseline CFD analysis of the main heat exchanger and cooling system for a medium duty EV truck showed that there were inefficiencies in the design. After discussing the root problem with the client, we quickly delivered a solution that increased the heat exchanger cooling capacity by over 65% as well as recommended avenues for improvement to reduce overall vehicle drag.