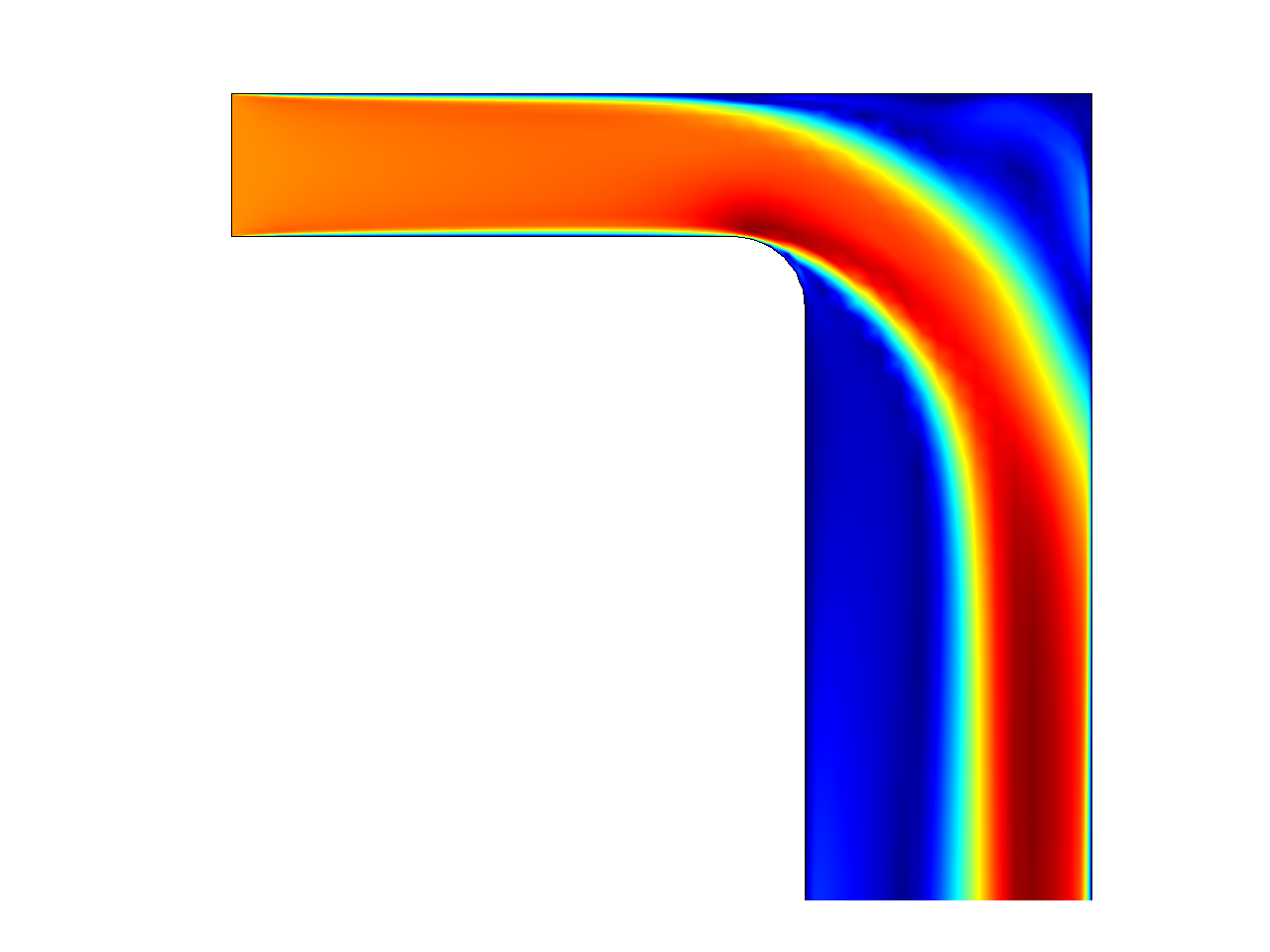

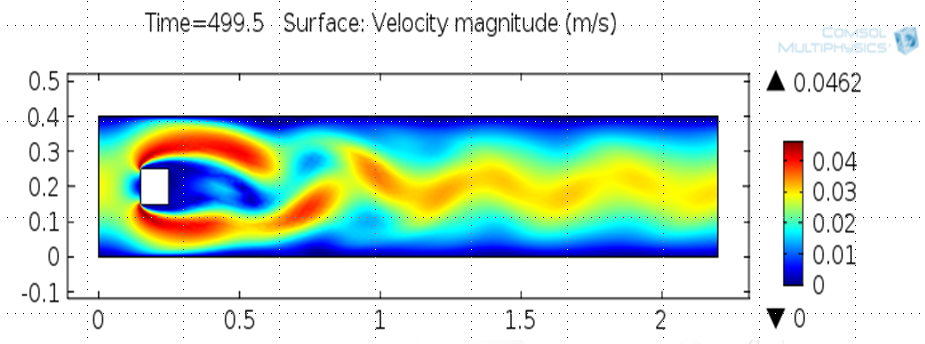

Many of tomorrow’s technologies will harness turbulent flows, such as combustors, reciprocating engines, turbines and forced air cooling of electronic devices. To analyze these applications, detailed tracking of the fluid dynamic, thermal and thermodynamic properties of the flow is often required – variables such as pressure, temperature, density, viscosity, reactant and product species, humidity, etc. Since the equations of fluid flow are nonlinear and the length and time scales of turbulence exist over a broad range, most applications are best analyzed with Computational Fluid Dynamics (CFD), that is, by simulating the fluid flow using computational analysis. In a CFD simulation, the governing equations of comsol fluid dynamics (Navier-Stokes) are solved iteratively, often by using a turbulence closure model, such as the k-ε model.

At AltaSim, we have experience enabling our clients to optimize their devices or reactors to maximize mixing, control turbulence and/or enhance heat transfer rates. AltaSim engineers do this by quantifying the flow field and visualizing mixing or heat transfer parameters for a range of conditions within the design space, so that the customer can more easily evaluate which process or geometry best meets their needs. By efficiently conducting CFD, discussing results and providing suggestions for design improvements, AltaSim partners with its clients to help them deliver better engineering solutions for their next generation products.

In addition, AltaSim also provides a comprehensive range of training on CFD: Computational Fluid Dynamics analysis with the following course:

Need Help with CFD Analysis?

Contact us about our CFD technology services.