Simulation Engineering describes the use of computer modeling and simulation to predict the behavior of engineering-based technologies using predictive scientific, engineering, computational and mathematical formulations, and in some cases it has been integrated with other approaches to include an evaluation of risks and benefits. The use of this technology has expanded in the past 10 years not only to characterize scientific theories but also to demonstrate new technology and lead the development of innovative commercial products. It is now applied to areas ranging from structural analysis of ship structures to design of semiconductor chips for microelectronic circuits, from atmospheric science to nanotechnology and from chemical reactions to bioengineering. Benchmark studies performed with DARPA have demonstrated that AltaSim Technologies' computer based Simulation Engineering can reduce the cost of new product and technology development by up to 90% and simultaneously reduce the cycle time for development by up to 50% compared to traditional iterative design-test evaluation- redesign approaches. AltaSim's approach integrates the fundamental physics of the relevant phenomena with an accurate representation of the product or process to allow real world design through the application of science. When coupled with our proprietary Lean Innovation and Virtual Product Development tools, our customers have seen the benefits in:

These simulation engineering approaches have been successfully applied to the full range of technology development and commercialization:

- Proof of concept: Demonstrate viability of technology for the intended purpose prior to large capital investment

- Prototype design: Design of product/process prototype with decreased time and cost to market

- Manufacturing technology: Identification of critical stages in the manufacturing processes that require control to maintain product performance

- Product extension: Development of second generation product/process design

- Product optimization: Identification of optimum product/process design with minimization of manufacturing operations and consolidation of components without loss of product functionality

The knowledge, understanding and insight gained from simulation engineering strengthen the customer’s technology foundation and provide a base for future innovation and technology implementation. Customers are able to apply market-focused product and technology development solutions to real world problems allowing them to innovate rapidly and gain competitive advantage by minimizing the time between concept development and successful implementation of commercially viable products. When coupled with our proprietary Lean Innovation and Virtual Product Development tools, our customers have seen the benefits such as:

- Increase the rate at which new designs of consumer products reach the market

- Redesign innovative medical technologies to function effectively and exceed initial performance targets

- Identify manufacturing tolerances for viable production of innovative communications technology

- Demonstrate viability of alternative energy based technology

- Optimize product performance and minimize product production cost

Originally viewed as the purview of highly-trained experts, AltaSim now seeks to cascade advanced multiphysics simulation engineering tools for independent use by scientists and engineers with limited or no expertise in computational analysis. Through the use of focused, self-contained predictive Multiphysics-based modeling and simulation applications, inexperienced users can independently assess the viability of new technologies. Applications have been developed to examine the following areas:

- Manufacturing process technology for CMC production

- Design of innovative microelectronic devices

- Development of patient specific treatment protocols

- Effect of imaging radiation on implanted medical devices

To discuss how AltaSim can help your technology developments, please contact us to arrange more detailed discussions.

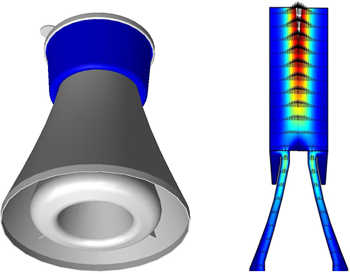

Mosquito trap designed using CFD

Need Help with Your Simulations?

Contact us about our Heat Transfer technology services.